In today’s industrial automation scenario, the most prominent technology associated with Industry 4.0 and the Industrial Internet of Things (IIoT) has been that of edge computing. So, until recently, “edge” terminology didn’t even make any sense. But now, information technology (IT) networks are being connected to operation technology (OT) networks, thereby putting OT controllers at the edge—from the perspective of IT.

So, when someone is talking about edge computing in the OT world, they might be referring to a PLC, though they might not even be aware of what it does. Another possibility is that, when someone is referring to edge computing with respect to OT, they might mean a PC employed in the OT world, such as an industrial PC (IPC). And just as with all the shifting that has taken place with “edge” terminology recently, the same has occurred with IPCs. We all remember the time when futurists prognosticated the end of the PLC when IPCs came out. Did this revolution come to pass? No. But if you look deep into a PLC or DCS today, what you’ll find is that it is just a computer. It might not run Windows, but this is likely the reason why IPCs didn’t wipe out PLCs—the blue screen of death is just too risky in a production environment.

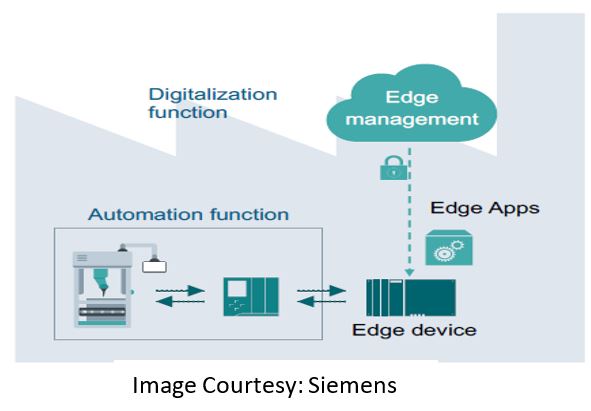

In the recent ARC India Forum 2019, Sheetal Paralikar, Business Development Manager, Siemens spoke about how PLCs and DCSs are being integrated with edge computing and analytics to provide greater benefits to predictive maintenance across the value chain of industries.

Sheetal outlined the major criteria for any industry sector to compete in the market with process optimization by taking care of the five major aspects of Speed, Flexibility, Quality assurance, Efficiency, and Security.

s through the decoupled, flexible plant expansion to include new features, such as preventive maintenance.

s through the decoupled, flexible plant expansion to include new features, such as preventive maintenance.Collecting and concentrating relevant production data of several sources

Protocol conversion/customer programmed control

Secure transfer to connected company IT systems or cloud applications

Production monitoring, analysis and optimization

ARC welcomes the opportunity to speak with technology suppliers and users alike about your activities, thoughts, perspectives and questions on this exciting area. For further discussion or to provide feedback on this, please contact the author Jyoti Prakash at jprakash@arcweb.com .

Keywords: Siemens, Advanced Automation, Edge Computing, AI, Interoperability, Predictive maintenance.