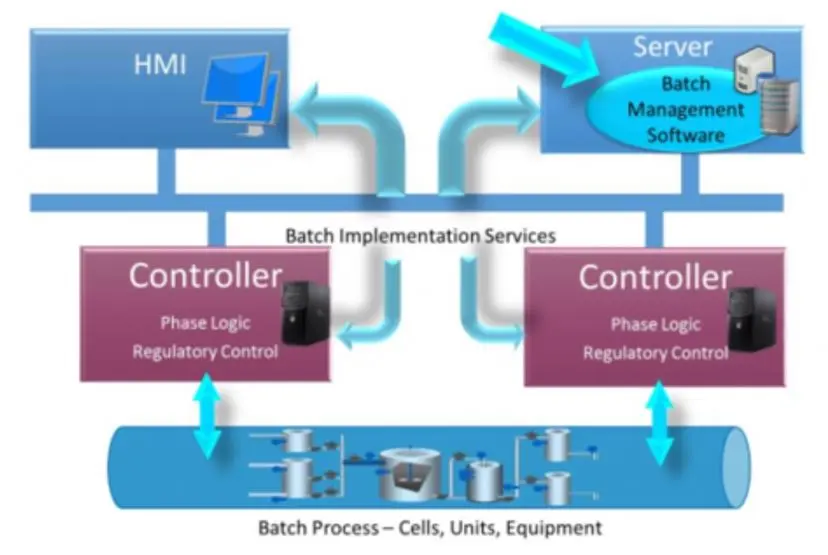

Batch Management Software (BMS) executes the Production Management functions specified in the ANSI/ISA-95 (IEC 62264) and ANSI/ISA-88 (IEC 61512) standards for the batch processes industries, including fine chemicals, life sciences, food, and beverage/CPG. It plays a supervisory role in directing process control functions and assumes an underlying controller architecture. The BMS is typically executed in a workstation or server and interacts with the control system, typically DCS, PLC, or other controllers, running phase logic or regulatory control manipulating field devices.

The batch services include configuring the batch management software, batch phase logic, batch related regulatory controls, batch displays, batch historian, and communication interfaces needed for batch control or distribution of batch data to other applications. The services category may include software license renewal for the batch management software or periodic maintenance of batch related application software (not including any hardware). Software components that are specifically used for the batch process control are also included, such as drivers, communications interfaces, batch historians, or batch related Manufacturing Execution System (MES) applications.

Batch management software helps automate batch processes, and it includes functions, such as managing batch recipes, executing top-level recipe functions, and tracking batch execution. The software supervises the execution of batches and typically includes the following capabilities:

Creating a control recipe from a master recipe

Assigning a unique batch identification (batch ID) to each batch and to the associated control recipe

Sizing the control recipe to meet the batch quantity needed

Maintaining all the current control recipes until the batches are completed

Modifying any part of a control recipe that has not been executed

Monitoring and controlling the execution of control recipe(s)

Maintaining batch status information

Recording event information on batches

Most batch software uses the ISA S88 batch process model, which uses SFC (Sequential Function Chart) methodology for batch execution. Batch automation can include inventory management of raw materials and finished products, material or path management tracking functions, and allocation of process units and other equipment. Some applications may completely automate material transfer or clean-in-place operations.

Batch production scheduling is a critical component of batch management software. It includes generating short-term production schedules and generating batch production dispatching data. A short-term production schedule is a collection of activities that take the longer-term production schedule to generate short-term scheduling requirements based on the optimal use of local resources 1. Production dispatching data is a collection of activities that manage the flow of production by dispatching production to equipment and personnel. This may involve scheduling the start of the batches, scheduling production runs, specifying standard operating condition targets in production units, sending work orders to work centers, and issuing work orders for manual operations 1.

Batch historian and reporting is another function of batch management software. This function includes storing and maintaining batch histories, generating reports based on event (batch, phase, etc.) and time, and generating batch performance analysis reports. The actual collection of batch production data is usually carried out by batch recipe management, execution, and tracking function. Data stored in the batch event historian can be collected and recorded as a transaction by higher-level ERP programs or applications.

The Batch quality management function includes testing and verifying the quality of materials, measuring, and reporting the capability of the equipment to meet quality goals, certifying product quality, and setting quality standards. It involves testing and verifying the quality of materials (raw, final, and intermediates).

Batch quality can be sampled and analyzed in a lab. Batch management software may have a communication link to a Laboratory Information Management System (LIMS) system in order to associate quality measurements with the batch. Batch quality can be directly measured with on-line analysis, and batch quality can also be assured.

By optimizing the use of local resources, batch management software can help businesses reduce costs and increase efficiency. It can also help businesses maintain quality standards and improve product quality.