On-off valves or shutoff valves control the on-and-off supply of media to or within a fluid or gas system. These valves can only start or stop the flow of the media by operating at the fully open or fully closed position. Unlike  control valves, these valves cannot regulate the rate of flow. An on-off valve installation consists of a valve body, actuator, switchbox, and accessories. The body includes a bonnet assembly and trim parts. Its design withstands fluid static pressure and differential pressure, allows fluid flow, provides pipe-connecting ends, and supports seating surfaces and a valve closure member.

control valves, these valves cannot regulate the rate of flow. An on-off valve installation consists of a valve body, actuator, switchbox, and accessories. The body includes a bonnet assembly and trim parts. Its design withstands fluid static pressure and differential pressure, allows fluid flow, provides pipe-connecting ends, and supports seating surfaces and a valve closure member.

An on/off valve is the fluid equivalent of an electrical switch: a device that either allows unimpeded flow or acts to prevent flow altogether. These valves are often used for routing process fluid to different locations, starting and stopping batch processes, and engaging automated safety (shutdown) functions.

These valves can only start or stop the flow of the media by operating at the fully open or fully closed position. Unlike control valves, these valves cannot regulate the rate of flow. An on-off valve installation consists of a valve body, actuator, switchbox, and accessories. The body includes a bonnet assembly and trim parts. Its design withstands fluid static pressure and differential pressure, allows fluid flow, provides pipe-connecting ends, and supports seating surfaces and a valve closure member.

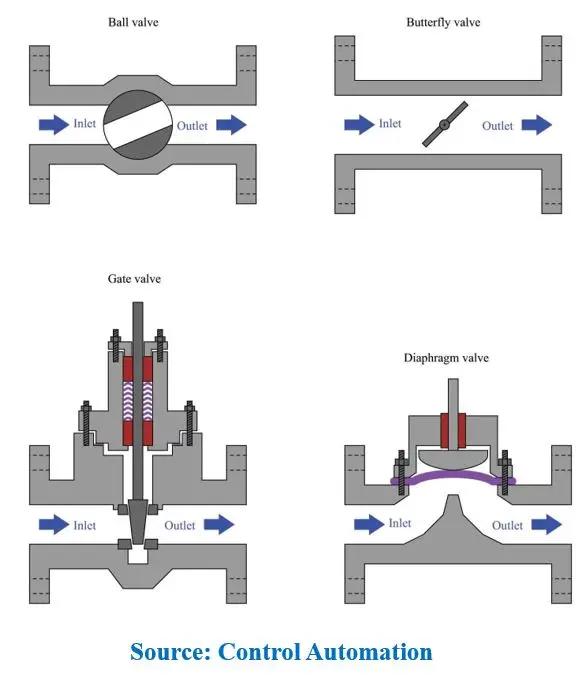

Valve styles commonly used for on/off service include ball, plug, butterfly (or disk), gate, and the globe. Large on/off valves are generally of such a design that the full-open position provides a nearly unimpeded path for fluid to travel through. Ball, plug, and gate valves provide just this characteristic.

Ball valves consist of a ball with a hole in the center that can be rotated to either allow or stop the flow of fluid or gas.

Gate valves consist of a gate or wedge that is lowered into a slot in the valve body to stop the flow of fluid or gas.

Butterfly valves consist of a disk that rotates to either allow or stop the flow of fluid or gas.

Globe valves consist of a disk that moves up and down to control the flow of fluid or gas through the valve.

Other types of on/off valves include:

Solenoid valves: use a linear sliding obstructer to open or shut the valve or redirect the flow from one outlet to another.

Coaxial valves: a 2-position valve that can be either pneumatically or electrically actuated.

Angle seat valves: a type of pneumatically actuated valve that is used for controlling liquids or gases.

A valve actuator is a mechanical device that uses a power source to operate a valve. There are two main types of actuators, one for each of the two main types of valves that require them. They are rotary and linear.

As the name implies, rotary valve actuators produce the rotational motion needed to operate rotary valves such as ball, plug, and butterfly valves. Rotary actuators are available in many different styles, each with its own benefits.

Linear valves such as globe, gate, and pinch valves - due to their distinctly different operation - require actuators that are drastically different from the rotary type. These actuators must produce linear motion to operate the valve.

On-Off valves can be actuated by a variety of mechanisms, depending on the specific application and requirements. The most common types of actuators used in On-Off Valves include:

Manual Actuators: Manual actuators are the simplest and most common type of actuator used in On-Off Valves. They consist of a handwheel or lever that is used to manually open or close the valve. Manual actuators are suitable for small valves and low-pressure applications where the valve needs to be operated infrequently.

Pneumatic Actuators: Pneumatic actuators use compressed air to open and close the valve. They are commonly used in industrial applications where the valve needs to be operated quickly and frequently. Pneumatic actuators are suitable for high-pressure applications and can be used in hazardous environments.

Electric Actuators: Electric actuators use an electric motor to open and close the valve. They are commonly used in applications where the valve needs to be operated remotely or where the valve needs to be opened and closed frequently. Electric actuators are suitable for both high-pressure and low-pressure applications.

Hydraulic Actuators: Hydraulic actuators use hydraulic pressure to open and close the valve. They are commonly used in high-pressure applications and can be used in hazardous environments. Hydraulic actuators are suitable for large valves and applications where a high level of precision is required.

Solenoid Actuators: Solenoid actuators use an electromagnet to open and close the valve. They are commonly used in low-pressure applications where the valve needs to be operated quickly and frequently. Solenoid actuators are suitable for applications where a high level of precision is not required.

Switchboxes monitor actuator movement and signals when an end position has been reached. Occasionally, the valve is directly controlled by the contacts of the switchbox. Accessories include electro-pneumatic transducers, pressure regulators, hand wheels, position indicators, and limit switches.