Keywords: Automation Fair, Digital Transformation, Artificial Intelligence, Generative AI, Industrial AI, Sustainability, Operational Resiliency, OEM, Smart Manufacturing, Co-Pilot, Cybersecurity, Autonomous Mobile Robots, Predictive Maintenance, ARC Advisory Group.

Rockwell Automation held its Automation Fair 2023 in-person event in Boston, MA on November 6-9, 2023. The company had in-person attendance of over 11,000 users and partners choosing from a number of product and technology sessions, industry forums, hands-on labs, and both Rockwell Automation and partner exhibits on the show floor. This year’s Automation Fair incorporated a previously separate event, ROKLive, and continued to incorporate the Rockwell Automation Process Solutions Users Group (PSUG).

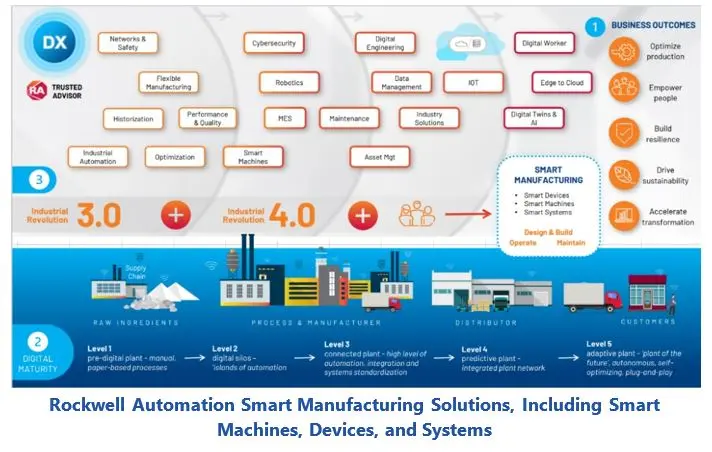

With a theme of discover what’s possible, Automation Fair provided a number of sessions focused on digital engineering and design, using digital production and processes to help design machines, manage production, accelerate time to value, enhance productivity, and help its customers advance on their digital transformation journey. It also provided a focus on operations management, empowering people and systems with accurate, real-time data that can help reduce downtime, improve goal attainment, and enable faster decisions. Also, smart manufacturing was a primary focus, including smart devices, systems, machines, industrial grade AI, and best practices, and how smart manufacturing can improve maintenance, uncover opportunities, boost quality, and increase efficiency as part of every manufacturer’s effort to be both more productive and more sustainable through digital insight, innovation, and value-chain impact on their respective net zero journeys.

Rockwell Automation’s executives conveyed their vision to the Automation Fair attendees in a number of keynote addresses. Blake Moret, Chairman & CEO of Rockwell Automation, shared his vision of a number of ways that Rockwell Automation helps to deliver innovative solutions that expand human possibility. Blake discussed how production can be better optimized and productivity improved by providing better visibility into operations, leveraging data to helps customers to respond more quickly to market changes, increase their speed to market, and drive business growth. This will also result in more agile supply chain planning, an upskilled workforce, improved sustainability, and the ability to achieve sustainability goals.

Blake emphasized how Rockwell Automation will continue to offer technology in the industrial metaverse that accelerates development in the digital world for the greatest impact in the physical world, providing digital transformation solutions that help to simplify complex challenges, build resilience, empower people, drive sustainability, and reduce energy usage. According to Blake, there are three key outcomes that will optimize production: resilience, agility, and sustainability, so that customers can make things better, faster, and cheaper. It is important to frame technology around people because of workforce shortages and equip people doing the work with tools that make them comfortable interacting with human factored technology.

Rockwell Automation had several senior executives from both inside and outside of Rockwell Automation present. One of these presentations that covered Rockwell Automation’s key strategies and technologies in depth was Cyril Perducat, Senior Vice President and CTO at Rockwell Automation, who discussed when we talk about the future, the use of technology is not about removing humans, it is about leveraging the technology to help people do their jobs better, augmenting workers skills and capabilities. Robotics and AI will assist humans to do their jobs better, as the future of industrial operations is about technology and people collaborating and working together, and AI is an extremely important part of this future.

According to Cyril, there are three challenges that industry must meet when creating the future of industrial operations that Rockwell Automation is helping users respond to. The first challenge is around constantly changing demands. Today manufacturers are making more customized and personalized products and need to retool their factories often to meet demand. The second challenge Rockwell Automation is addressing is supply chain volatility. Personalized manufacturing and production are about optimizing tasks and needs to be combined with the ability to manage supply chain volatility. It is important that the right product is manufactured at the right time at the right cost. The product must be produced safely and adapted to an incoming supply chain that changes quickly because of geopolitical factors or because of the shortage of raw materials. The third challenge that continues to impact industry is increasing targeted cyberthreats to industrial operations. Rockwell Automation has developed technologies and services that address cyberthreats, and their recent acquisition of Verve will help to further enhance these capabilities.

Cyril discussed how the future will be to go from flexible connected machines with plug and play that enable fast changeovers to reconfigurable manufacturing systems for simplified updates, which is why Rockwell Automation is integrating the machines into the IT architecture of its customers. Once users have the ability to reconfigure the connected environment with the right level and flow of data, they need to consider the evolution of digital twins. Digital Twins can be many things including enabling a machine or production line design and includes the ability to understand the physical world with digital reality for multidimensional optimization with a digital product lifecycle integration that enables constant evolution. Digital twins enable the ability to optimize production and to produce custom products or batches of one. If you can optimize production, it means that you can also re-optimize after production changes.

Cyril talked about another dimension of process optimization, which is consideration of how the materials used in production become part of the product lifecycle design. Having data from closed loop systems can also help reduce consumption and contribute to sustainability. It is also important to make products more sustainable by taking renewable energy sources and fully integrating renewable energy sources such as drawing power from solar or from the grid and modifying the production schedule to the most cost-effective times. It also means integrating processes that increase carbon capture and deploy viable energy models.

There is also a new set of tools merging machine learning and analytics into a technology that uses AI for closed loop optimization to analyze the production lines and processes better and faster. AI can reprogram the process based on the data to better optimize the closed loop control algorithm with the right parameters. The worker can focus on the business problems that need to be optimized instead and use the tools for the desired business outcome.

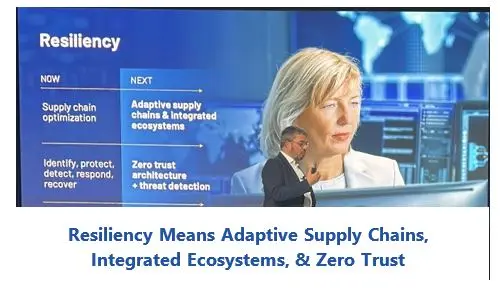

Regarding resilience, Cyril explained that supply chain optimization leads to adaptive supply chains and integrated ecosystems. This requires automating material movement by making it part of the production line and developing synergies between the control environment and the supply chain. The supply chain will also be improved by better integration with an ecosystem of partners. Resilience also means that cybersecurity goes beyond just identifying, protecting, detecting, responding, and recovering, and includes having a zero-trust architecture with the right threat detection for industrial production that often follows IT standards.

Regarding people, Cyril talked about the need to simplify things on the human front in help increase human possibility, with predictive maintenance systems adding natural language interrogation, and the use of technologies, such as Copilot in design tools, to enables workers to better drive optimization with AI enabled code sharing, code generation and verification. Rockwell Automation’s Copilot is creating a modern AI-like ChatGPT that creates a different type of experience to enable workers to better understand what is occurring and help them make better decisions. Also, by integrating autonomous mobile robots (AMR) and intelligent convenance for material movement into the overall production system helps to augment people by not having to perform manual and repetitive steps and eliminating many possibilities of workplace injuries, while simultaneously increasing productivity and efficiency.

Judson Althoff, Chief Commercial Officer, Microsoft joined Blake Moret to discuss their joint cloud application journey and partnership with Rockwell Automation. Judson discussed how the industrial Metaverse is a space where technology and people come together jointly to have a real-world impact on automation projects to help people build better products more effectively and efficiently. The industrial metaverse is the culmination of IoT capabilities, cloud scale data stores, artificial intelligence, mixed reality, and digitalization and other capabilities, such as 3D Digital Twins that can simulate any type of manufacturing environment. It also includes supply chain and logistics software that helps drive efficiencies. Rockwell Automation will continue to work with Microsoft around the concept of the Industrial metaverse. Judson also discussed that Microsoft is seeing massive gains in sustainability using the technology to simulate a manufacturing process virtually in the cloud first to build a better product more effectively, more efficiently to drive energy savings, reduce water, and increase efficiencies.

Judson also discussed Rockwell Automation and Microsoft working on a cogeneration project that uses generative AI with a Copilot at the front end of Rockwell Automation’s advanced configuration tools. Microsoft is infusing generative AI into every product built at Microsoft. Generative AI is being used to build general AI capabilities. Microsoft’s GitHub Copilot is responsible for writing 30 percent of the code for Microsoft’s Copilots. It is giving Microsoft a time-to-market advantage and delivering added capabilities across to its portfolio.

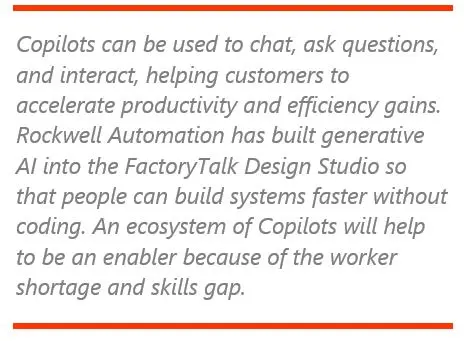

Microsoft is bringing AI to the Rockwell Automation portfolio with Microsoft’s Copilot that augments and teaches humans in a digital feedback loop. Copilot uses computer vision technologies and predictive AI to determine the next actions to troubleshoot an environment. Copilot uses natural language capabilities that can be used in business environments. Copilots can be used to chat, ask questions, and interact, helping customers to accelerate productivity and efficiency gains. Rockwell Automation has built generative AI into the FactoryTalk Design Studio so that people can build systems faster without coding. An ecosystem of Copilots will help to be an enabler because of the worker shortage and skills gap.

One of the highlights of Automation Fair are the nine Industry Forums, focused on the Process, OEM, Automotive/Tire, Life Sciences, Chemical, Warehousing/Logistics, Food & Beverage, Pulp & Paper, and Water/Wastewater industries. Highlighting one of the industry forums is how OEMs are delivering today’s value and realizing tomorrow’s potential with smart machines. The forum was moderated by Craig Resnick, Vice President at ARC Advisory Group, and featured a panel that included Paolo Butti, VP of Global Industry-OEM, Rockwell Automation; Peter Barrie, Product Management Director, Sani-Matic; Seth Walters, Vice President of Engineering-Simmons Foods; Billy Goodman, Managing Director-Cama North America; Antonio Ambra, Managing Director–AIC Group; George Young, Vice President, Digital-Rockwell Automation; and Maddie Blanchard, Global Digital Sales Executive-Rockwell Automation. Discussion centered around how smart manufacturing requires smart machines that produce data contextualized for valuable insights, easily connect to other infrastructure, and adapt to changing production and workforce requirements. Tomorrow’s smart machines will leverage AI and machine learning to push the boundaries of intelligent automation.

The OEM forum drilled into several critical topics, such as Paolo Butti discussing how OEMs are so key to the Smart Manufacturing Ecosystem, and Peter Barrie explaining how the external adoption of smart machines is critical, the internal challenges OEMs face with the development and launch of smart machines, and the recurring SaaS revenue and other benefits that smart machines bring. Seth Walterson and Billy Goodman discussed the technologies that are critical to smart machines such as selecting control platforms and components, how smart machines increase machine performance, production capacity, growth and business results, and challenges or obstacles that smart machines bring to operations that were faced and how they were overcome.

Antonio Ambra discussed the challenges in convincing customers to deviate from status quo and going to smart machines, such as using a single controller instead of having the proven robot controller that usually comes with the robotic arm, the use of robotic applications and AI, and forecasting where smart machines will be in 10 years from now. And George Young and Maddie Blanchard discussed Kalypso, which is Rockwell Automation’s Digital Service Arm, and how they work with smart machine OEMs globally and some of their success stories. Based on the strong attendance of the OEM Forum at Automation Fair and the number of audience questions, there is no doubt that smart machines are of significant interest to both the OEM machine builders as well as the end users across all manufacturing and processing industries and to expect strong market growth in the sector.

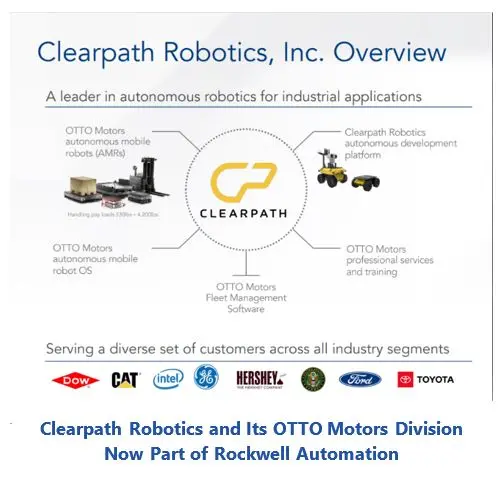

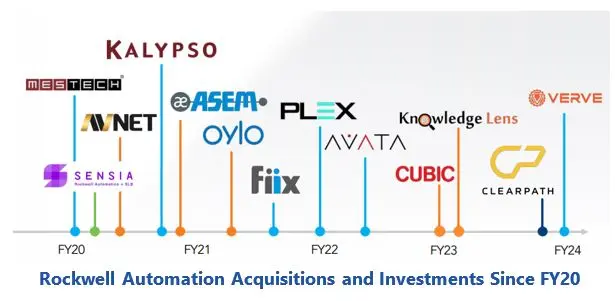

Rockwell Automation made a number of announcements and introduced a multitude of new solutions at or just before Automation Fair 2023 in time so they may be showcased. Some of the ones that were prominently features at Automation Fair included Rockwell Automation acquiring Ontario, Canada-based Clearpath Robotics, an autonomous robotics supplier for industrial applications. Founded in 2009, Clearpath got its start offering robotics technology to global research and development markets, and in 2015, launched its OTTO Motors Division, which offers AMRs and fleet management and navigation software that helps to increase throughput and reduce costs by moving components and subassemblies to the place where they are needed and by transporting finished goods to a truck or warehouse upon completion.

Combined with Rockwell Automation’s continuing partnerships in fixed robotic arms, solutions such as Independent Cart Technology, and its installed base of programmable logic and automation controllers (PLCs and PACs), the addition of OTTO Motors’ AMR capabilities will create a broader portfolio of advanced material handling solutions. Data from Rockwell Automation’s offerings and OTTO Motors’ AMRs will be harnessed in artificial intelligence-powered Software as a Service information management applications, such as those by Rockwell Automation’s Plex and Fiix businesses. With this, Rockwell Automation will deliver a more unified solution for manufacturing, enabling autonomous execution and optimization to help increase efficiency and allow for traceability and real-time adjustments.

Rockwell Automation and Microsoft announced an extension of their partnership to help accelerate industrial automation design and development through generative artificial intelligence (AI). Both companies are combining technologies to help further empower the workforce and accelerate time-to-market for customers building industrial automation systems. The first outcome of this collaboration will add Microsoft’s Azure OpenAI Service into FactoryTalk Design Studio to help engineers to generate code using natural language prompts, automating routine tasks, and improving design efficiency. Rockwell Automation and Microsoft see a future in extending this integrated technology to solve other challenges, including quality management and improvement, failure mode analysis, and training frontline workers to execute manufacturing processes through chat-based collaboration with experienced human workers as well as Azure Open AI Service-based chatbots.

Rockwell Automation announced that it has signed a definitive agreement to acquire Verve Industrial Protection, a cybersecurity software and services company that focuses specifically on industrial environments. This acquisition will expand the offerings of Rockwell Automation with the addition of Verve's asset inventory system and vulnerability management solution.

The Verve Security Center platform helps to provide users with real-time asset inventory, vulnerability management, and risk remediation. The platform was built to provide IT-level security while addressing the challenges of the OT environment. The Verve platform is an asset inventory system that recognizes manufacturer's industrial assets with its proprietary approach that communicates directly with the assets, gathering information without impacting network performance and interrupting production. It then aggregates a range of data sources, including Rockwell Automation’s partner technologies, into its platform as a “single pane of glass” that provides actionable insights for customers to address their highest risk assets more quickly. Verve professional services also provides ongoing remediation, along with strategic roadmap and business case development, which further deepens Rockwell Automation’s cybersecurity consulting capabilities.

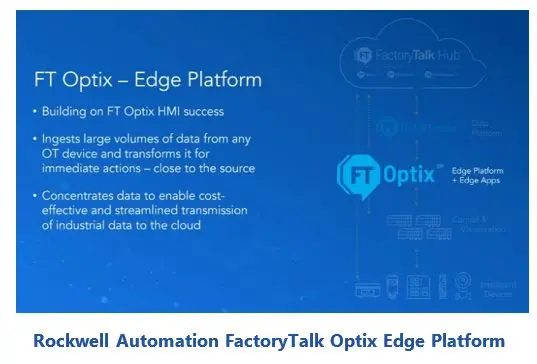

Rockwell Automation announced the launch of its FactoryTalk Optix portfolio, which is designed to help enable industrial organizations to build more versatile human machine interface (HMI) solutions The FactoryTalk Optix portfolio provides an open architecture along with options for design, deployment, connectivity, and extensibility. It includes Rockwell Automation’s HMI platform and remote access software, as well as Embedded Edge Compute Modules. FactoryTalk Optix software provides object-oriented design, wizard-based workflows and pre-built libraries and allows users to choose their own technology mix. Rockwell Automation customers can use visualization software to design HMI applications that can natively work with both Rockwell Automation and third-party controllers and run it on their choice of hardware. Users can connect to a variety of systems using software designed for interoperability and OPC UA support. Users also only pay for the features they need, helping to reduce spending on unused features.

FactoryTalk Optix Software is an HMI visualization platform that is accessed from browsers or downloaded on computers. It features multi-user collaboration, web-based design and test and integrated version control.

OptixPanel Graphic Terminals are sealed HMI appliances that come pre-loaded with FactoryTalk Optix and FactoryTalk Remote Access software licenses. The device can be used as a single solution ready to run at power-up.

FactoryTalk Remote Access provides secure remote connectivity, so users can view, assist, manage and troubleshoot from any remote location. It can connect domain experts to critical issues regardless of the physical location.

ASEM 6300 Industrial PCs are available in box or panel form and allow for greater customization. FactoryTalk Optix software enables seamless deployment of HMI solutions to the ASEM 6300 device that best fits applications.

Embedded Edge Compute Module provides a packaged solution for users to process visual data locally and remotely while maintaining the capability to grow and scale system as their needs change.

FactoryTalk Optix software V1.2 is now available with over fifty new capabilities, and it is available in English, Italian, French, Spanish and Chinese.

Rockwell Automation launched a new artificial intelligence (AI) predictive maintenance product, Asset Risk Predictor, from Fiix, the company's cloud-based computer maintenance management system (CMMS) business. Asset Risk Predictor (ARP) is the second offering from Fiix and uses AI analysis of sensor data, machine recipe, and operational environments to predict asset health, which helps users to spot and eliminate failures before they happen. The tool is capable of rapidly learning the signs of equipment failure and predicting breakdowns. Asset Risk Predictor can be purchased and used independently from a Fiix CMMS or can be integrated into the CMMS. When Asset Risk Predictors are connected to the CMMS, users can react to potential failure faster by automatically creating work orders in their CMMS.

Rockwell Automation announced a partnership with Everactive, a Santa Clara, CA-based supplier of wireless and batteryless condition-monitoring. Everactive’s solutions will complement Rockwell Automation’s Dynamix product line, which will help provide insights from rotating equipment assets without the concern of replacing batteries. The integrated system will provide data to Rockwell Automation's FactoryTalk MaintenanceSuite for asset monitoring, condition-based monitoring, and predictive maintenance programs. The combined solution will provide benefits for wireless sensor condition-monitoring applications where replacing batteries is a challenge.

Rockwell Automation and Infinitum announced an exclusive agreement to jointly develop and distribute a new class of high efficiency, integrated low voltage drive and motor technology. This solution is designed to help save energy and cut costs for customers to reduce their carbon footprint and become more sustainable. Under this agreement, Rockwell Automation’s PowerFlex drive technology will be combined with Infinitum’s Aircore EC motor system. This integrated variable frequency drives (VFDs), and motors package will help companies to reduce their carbon footprint with a motor system that is up to 50 percent smaller and lighter, uses up to 66 percent less copper, and consumes up to10 percent less energy than traditional iron core motors. Rockwell Automation and Infinitum have collaborated since 2021, when Rockwell Automation made an initial investment in Infinitum as part of the company’s Series C funding.

Rockwell Automation announced the release of a new line of Allen Bradley Stratix 5200 fully managed switches that are designed to be easier to set up, configure and offer more enhanced security features. Stratix 5200 switches offer various hardware configurations and features that include expansion of higher port speed options with all gig SKUs, redundant and resilient architecture options that support fully managed and high-performance switch tiers, a more simplified portfolio, and switch selection that is streamlined to be fully managed and offer higher performance.

Stratix 5200 fully managed switches are based on the Cisco IOS XE platform that includes a new graphical web user interface, enhanced troubleshooting tools, fundamental disaster recovery features, and customizable dashboards. They also align with Cisco Cyber Vision Sensor options and tie into Cisco TrustSec software for a defined segmentation approach. These switches offer fundamental protection against counterfeit hardware and software risks and additional encryption options. The Stratix 5200 switch includes a set of switching features that comply with international standards, such as IEC 62443-4-2 for cybersecurity, as well as providing port security and access control lists.

Rockwell Automation clearly demonstrated at Automation Fair that it continues to make advances in its technological offerings, solutions, and services, which supported the event’s theme of expanding human possibility. The company continues to expand their technologies helping to make it simpler for users to manage complex processes while expanding their solutions to address supply chain challenges, minimize environmental impacts, accelerate the journey toward net zero carbon production, and better optimize material and resource consumption. The company is integrating industrial grade AI and robotics into their technologies to help augment people and further optimize production. The company has developed a zero-trust architecture that integrates AI and helps to defend against cyber threats. They have also developed a natural language co-pilot that generates code for developers and helps to better optimize processes. The company has a strong ecosystem of partners and has made many acquisitions over the past few years that help to better support the future of industrial operations.

One of the biggest challenges manufacturers and processors face today continues to be how to help its workforces that are often smaller in number and less experienced assume multiple roles and responsibilities and simultaneously become more productive and efficient. This challenge can be addressed by thoughtfully adding AI capabilities that help workers accelerate their productivity of developing and deploying solutions. Rockwell Automation is in a strong position to accelerate its user’s productivity and efficiency for designing and deploying solutions for design, visualization, digital twin, storage, remote access, etc. AI can become a critical productivity tool that workers will require and request for all their tasks, providing them with a virtual digital assist that will become ubiquitous regardless of role, and Rockwell Automation will become a critical source for providing and supporting industrial grade AI technology to their customers as it is embedded in their solutions and services.

ARC Advisory Group clients can view the complete report at the ARC Client Portal.

Please Contact Us if you would like to speak with the author.

Obtain more ARC In-depth Research at Market Analysis